karthik@mmsankhlaelectricals.com 08048783231

- Send SMS Send Email

Polycab Products

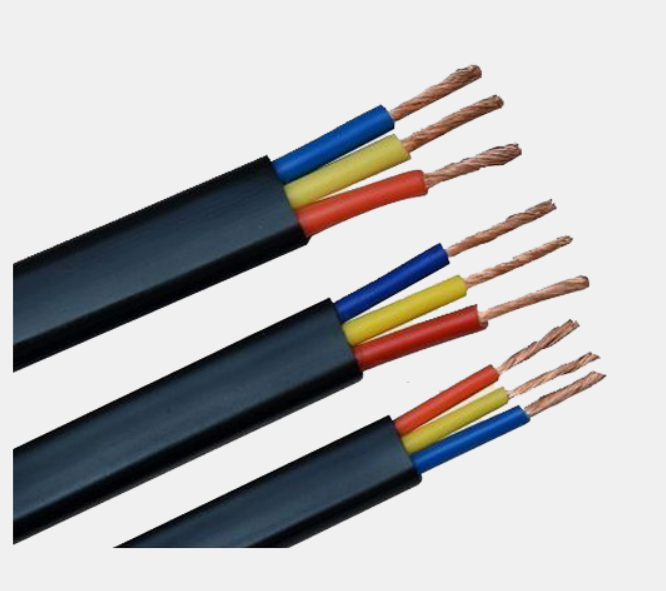

Leading and Distributor of 3 Core Flat Submersible Cables, High Tension XLPE Cables, PVC Insulated Heavy Duty Cables and XLPE Insulated Heavy Duty Cables from Bangalore.

| Business Type | Trader, Distributor |

| Thickness | 0.5-1mm |

| Length | 20-30mtr, 30-40mtr |

| Color | Black, Red, White, Yellow |

| Feature | Crack Free, High Ductility |

| Country of Origin | India |

| Manufacturer | Polycab |

Preferred Buyer From

| Location | Anywhere in India |

Polycab Special 3 Core Flat Cables are manufactured for critical space requirement, protection against indefinite immersion in water under specified conditions, protection against rain-water and against ingress of small solid foreign bodies.

Polycab Special 3 Core Flat Cables are produced form best quality electrolytic copper, which is drawn, annealed on-line and bunched on automatic machines to ensure flexibility and uniform resistance. The conductors are insulated with a special grade of PVC on sophisticated co-extrusion lines. Outer sheath consists of highly abrasion resistant PVC compound impervious to grease, oil and water etc.

| Business Type | Trader, Distributor |

| Application | Heavy Duty Sealing |

| Color | Black, Brown, Grey, Light Red, Silver |

| Conductor Material | Copper |

| Specification | Heat Resistant |

| Brand Name | Polycab |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

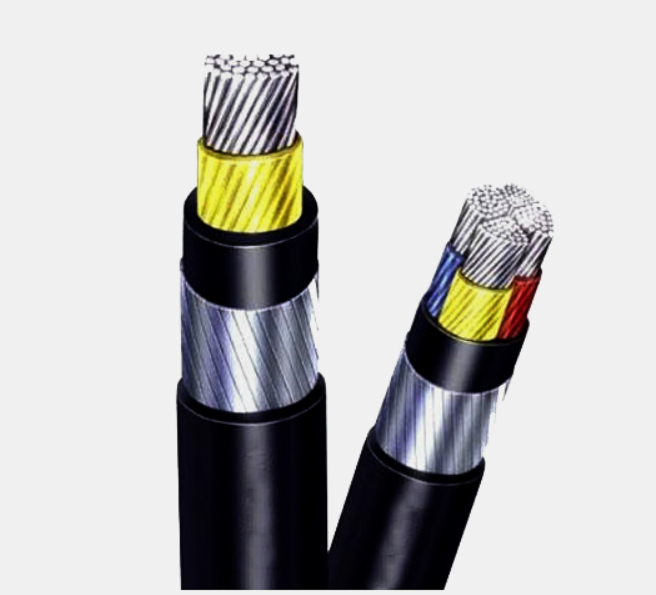

POLYCAB HV XLPE cables are manufactured at its most modern manufacturing setup in DAMAN. Manufacture of HV XLPE CABLES requires great care and skill at all stages of processing. Work on HV cables has shown to raise the electric stress of XLPE cables it is essential that the extruded insulation is of high cleanliness without any imperfection, free of contamination, voids and manufacturing defects, and that the screen interface is smooth. In addition an integrated extrusion plant employing a Continuous Centenary Vulcanizing (CCV) process line (Dry Curing Line) is required. Polycab easily met these two criteria by carefully selecting imported insulating materials and by installing 2 CCV lines sourced from world renowned manufacturers.

The cable core is triple extruded and crosslinked in the fully enclosed process in which the inner “semi-conducting” screen, the XLPE insulation and the outer semi conducting screen are applied simultaneously to the pre-heated cable conductor. Specialized in-line inspection techniques using X-rays are employed to monitor the dimensional accuracy of the extruded core. These examinations confirm the correct levels of dimensional accuracy.

The final stage of HV cable manufacture is the high voltage test, which comprises an HV withstand, and a partial discharge detection test. These tests take place in Polycab’s sophisticated HV Test Lab . The tests are of short duration, typically 30 minutes, and are capable of detecting the defects that initiate partial discharges, as small as one “pico-coulomb”. Such defects lead to gradual deterioration of the XLPE and eventually breakdown may occur.

| Business Type | Trader, Distributor |

| Thickness | 0.5-1mm |

| Certification | CE Certified |

| Length | 30-40mtr, 40-50mtr |

| Color | Black, Green, Red, White, Yellow |

| Feature | High Ductility |

| Country of Origin | India |

| Manufacturer | Polycab |

Preferred Buyer From

| Location | Anywhere in India |

The most acceptable metals for conductors are copper and aluminium due to their higher conductivity and ductility.

As copper has got higher affinity for sulphur, it corrodes in the atmosphere where sulphur fumes are present. In these conditions tinned copper should be used. Aluminium oxide film which is always present on Aluminium conductor surface acts as barrier and it protects the Aluminium conductor from corrosion in fumes laden atmosphere.

| Business Type | Trader, Distributor |

| Type | Xlpe Cables |

| Application | Heavy Duty Sealing, Locking Purpose |

| Grade | Domestic Grade, Industrial Grade |

| Color | Black, Brown, Grey, Light Red |

| Voltage | 220V |

| Specification | High Voltage |

Preferred Buyer From

| Location | Anywhere in India |

XLPE insulated heavy duty cables were introduced worldwide in mid sixties. These cables have overcome the limitations of PVC Insulated Cables such as thermal degradation, poor moisture resistance and thermoplastic nature.

Technical Advantages:

- Higher current rating, higher short circuit rating approx. 1.2 times that of PVC.

- Thermosetting in nature.

- Higher insulated resistance 1000 times more than PVC cables.

- Higher resistance to moisture.

- Better resistance to surge currents.

- Low dielectric losses.

- Better resistance to chemicals.

- Longer service life.

- Comparatively higher cable operation temperature 90 C and short circuit temperature 250 C

Commercial Advantages:

- Lower laying cost because of comparatively smaller diameter of cable and higher weight*.

- Lower installation charges as the diameter of cable is comparatively lesser with smaller bending radius, requiring less space requirement for laying cables.

- One size lower cable can be used as compared to PVC insulated cable.