karthik@mmsankhlaelectricals.com 08048783231

- Send SMS Send Email

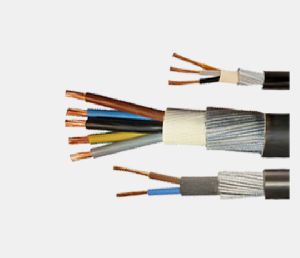

High Tension XLPE Cables

| Business Type | Trader, Distributor |

| Application | Heavy Duty Sealing |

| Color | Black, Brown, Grey, Light Red, Silver |

| Conductor Material | Copper |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

POLYCAB HV XLPE cables are manufactured at its most modern manufacturing setup in DAMAN. Manufacture of HV XLPE CABLES requires great care and skill at all stages of processing. Work on HV cables has shown to raise the electric stress of XLPE cables it is essential that the extruded insulation is of high cleanliness without any imperfection, free of contamination, voids and manufacturing defects, and that the screen interface is smooth. In addition an integrated extrusion plant employing a Continuous Centenary Vulcanizing (CCV) process line (Dry Curing Line) is required. Polycab easily met these two criteria by carefully selecting imported insulating materials and by installing 2 CCV lines sourced from world renowned manufacturers.

The cable core is triple extruded and crosslinked in the fully enclosed process in which the inner “semi-conducting” screen, the XLPE insulation and the outer semi conducting screen are applied simultaneously to the pre-heated cable conductor. Specialized in-line inspection techniques using X-rays are employed to monitor the dimensional accuracy of the extruded core. These examinations confirm the correct levels of dimensional accuracy.

The final stage of HV cable manufacture is the high voltage test, which comprises an HV withstand, and a partial discharge detection test. These tests take place in Polycab’s sophisticated HV Test Lab . The tests are of short duration, typically 30 minutes, and are capable of detecting the defects that initiate partial discharges, as small as one “pico-coulomb”. Such defects lead to gradual deterioration of the XLPE and eventually breakdown may occur.

Looking for "High Tension XLPE Cables" ?

Explore More Products